Balter Brewery approached RWTS with the need for an upgraded trade wastewater treatment system to handle their steadily increasing daily load.

The Issue | An overrun wastewater treatment system

The wastewater treatment system procured originally was designed adequately for the daily load of 3000 litres and was sufficient for the brewery’s early beginnings. However, due to Balter’s growing popularity, production has both increased and improved. This lead to daily site hydraulic loads of the wastewater treatment solution exceeding its designed capacity.

As such, the system design was essentially overrun, creating operational and reliability issues. This resulted in a system that could not perform correctly and meet the hydraulic demands the site was experiencing. In addition, we saw the potential to add significant value and functionality to the brewery’s waste treatment system design.

The RWTS Solution

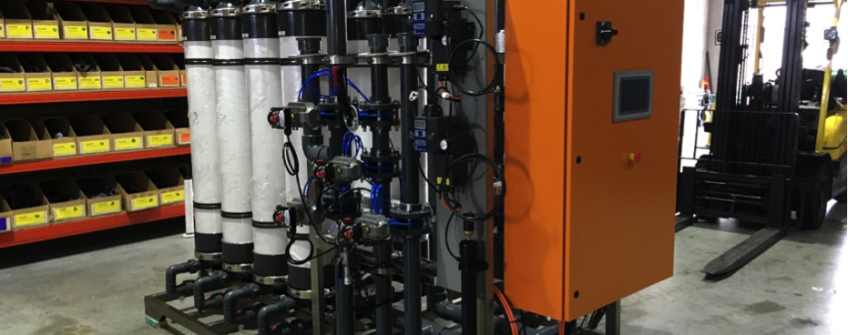

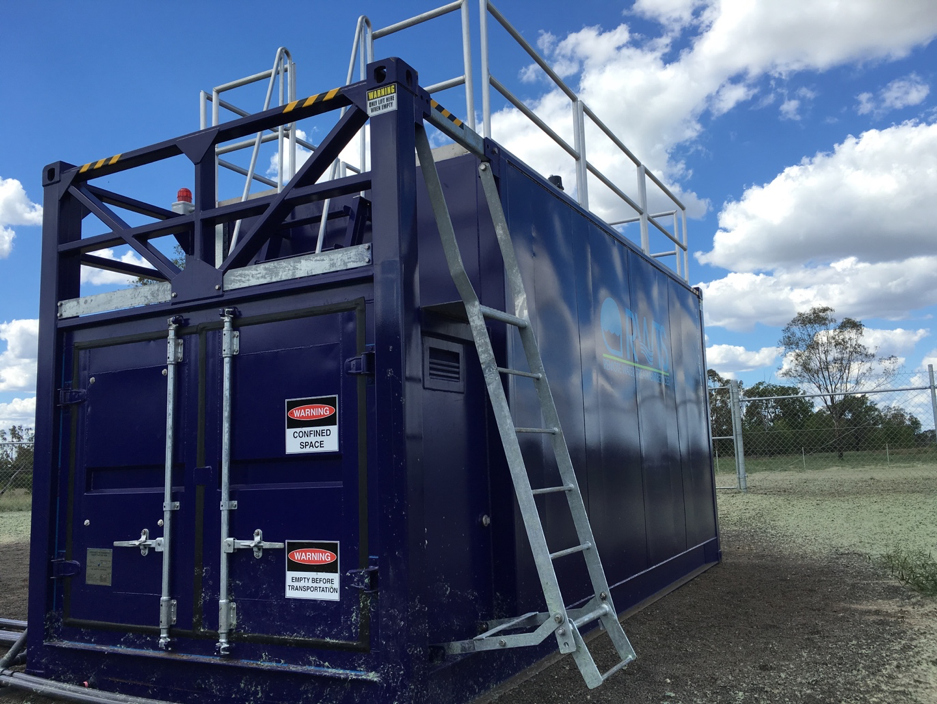

We proposed, designed and developed an enhanced system to not only ensure reliable operation, but to allow the comfortable treatment of 20,000 litres per day (that’s a lot of beer!).

By integrating advanced wastewater treatment technology, the new design allows for remote monitoring of the entire system operation, minimising the need for operator intervention and unnecessary maintenance. In short – more insight, less work. The HMI will provide a flow log and pH log each time the system discharges to trade waste on a daily basis. Data from the system can be stored for a minimum 30-day log and potentially up to 60 days.

If your brewery is looking for a wastewater treatment solution that provides detailed insight in real time but requires minimal operator intervention, we would love to discuss a tailored solution with you.