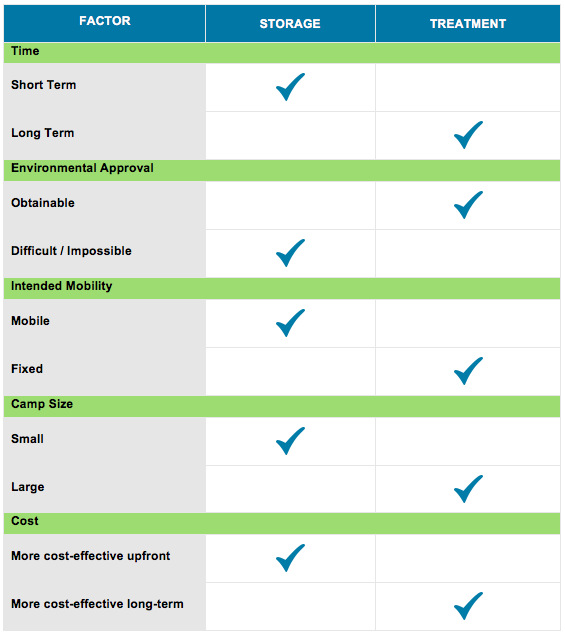

1. TIME

How long is your site realistically going to be in operation?

Short-term

A short-term site with a lifespan of just 1-8 months will likely see greater benefit in water storage.

Why?

- Reduced capital investment – Any water treatment plant will likely not in operation for long enough to offset the greater investment of such a system.

- Rapid deployment – Water storage options such as tanks or the WaterBox, offer the advantage of rapid deployment. These are pre-packaged products that can be transported to site on short notice.

- Environmental approval takes time – A tailored wastewater treatment system requires environmental approval from the state’s environmental regulatory body in order to discharge effluent onsite. This is often a time-intensive process and, depending on the terrain of your site, may not be feasible for your site or project timeline.

Long-term

If your site will be in operation for longer than 8-12 months, looking to an onsite wastewater treatment plant will likely be worth your while.

Why?

- Pump-out fees will be too expensive – Although a more costly investment upfront, by integrating a wastewater treatment system you will be forgoing the costly pump-out fees of transporting your wastewater to an approved discharge location. This may be justified on a short-term project, but over time this will chew through the budget significantly.

- Treated wastewater can be reused – Depending on your site, the treated wastewater can be used for local irrigation, reducing the demand on potable water.

2. Environmental Regulation

Environmental bodies have rigid regulations when it comes to discharging treated wastewater to the land. This can make the process of having a wastewater treatment plant approved a difficult endeavour, and even impossible when the terrain is not permissive of irrigation (e.g. close proximity to a bore, watercourse, wetland or spring).

Should your plans not comply with regulation, wastewater storage may be your only option.

REFERENCE / FURTHER INFORMATION:

3. MOBILITY

Mobile

Is your camp likely to be relocating on a regular basis? If so, a wastewater storage solution will be the better option. The WaterBox has been optimised for such circumstances and can be relocated with a 12-tonne forklift or crane. It’s shipping container design also lends it to easy compatibility with any truck/train transport.

Fixed

Wastewater treatment systems tend to be far more difficult to relocate, and commission and decommission. Taking all other factors into consideration, these are far better suited to camps that will be in a fixed location for a prolonged period.

If you are looking for a turnkey wastewater treatment system that can move with your camp, discover the EcoFarmer.

4. CAMP SIZE

Similar to the factor of time, the size of your remote camp will impact the volume of wastewater produced.

Small

For a small camp consisting of up to 100 people, less wastewater will generally be produced and therefore, wastewater storage may be more feasible.

Large

For a larger camp accommodating over 100 people, the volume of wastewater produced would likely be in excess of what mere storage could handle. This increased load would lend itself to a wastewater treatment solution being integrated.

5. COST

At this point, you’ll understand that many factors will impact the cost of a wastewater management system, but generally:

- for a short-term or mobile project, wastewater storage will be more cost-effective.

- for a long-term, fixed project, onsite wastewater treatment will be more cost-effective.

Below we’ve outlined the primary costs (other than the cost of the system itself) associated with each option:

Wastewater Storage

- Wastewater pump out – Only licensed liquid waste transport operators can legally transfer wastewater to an external facility. Due to the environmental, public health and workplace safety risks of transporting such high volumes of sewage, the cost of liquid waste removal services can be extremely high.

Wastewater Treatment System

- System maintenance – A wastewater treatment plant will require regular maintenance to ensure the ongoing efficiency of the system. Neglected plants with built up residue will eventually break down and require expensive repairs or replacement. We recommend a cleaning-in-place (CIP) system to ensure the long-term health of your plant.

- Chemicals and consumables – In order to treat the wastewater, chemical dosing is generally required. Therefore, there is an ongoing cost of ensuring there is sufficient inventory to keep the system in operation.

We’re here to support you

The experienced team at RWTS is always available to guide and support you in developing the best wastewater management system for your project. For a truly tailored approach, get in touch with us today. We’ll handle the complexities of system design, leaving you with a streamlined, user-centred solution.