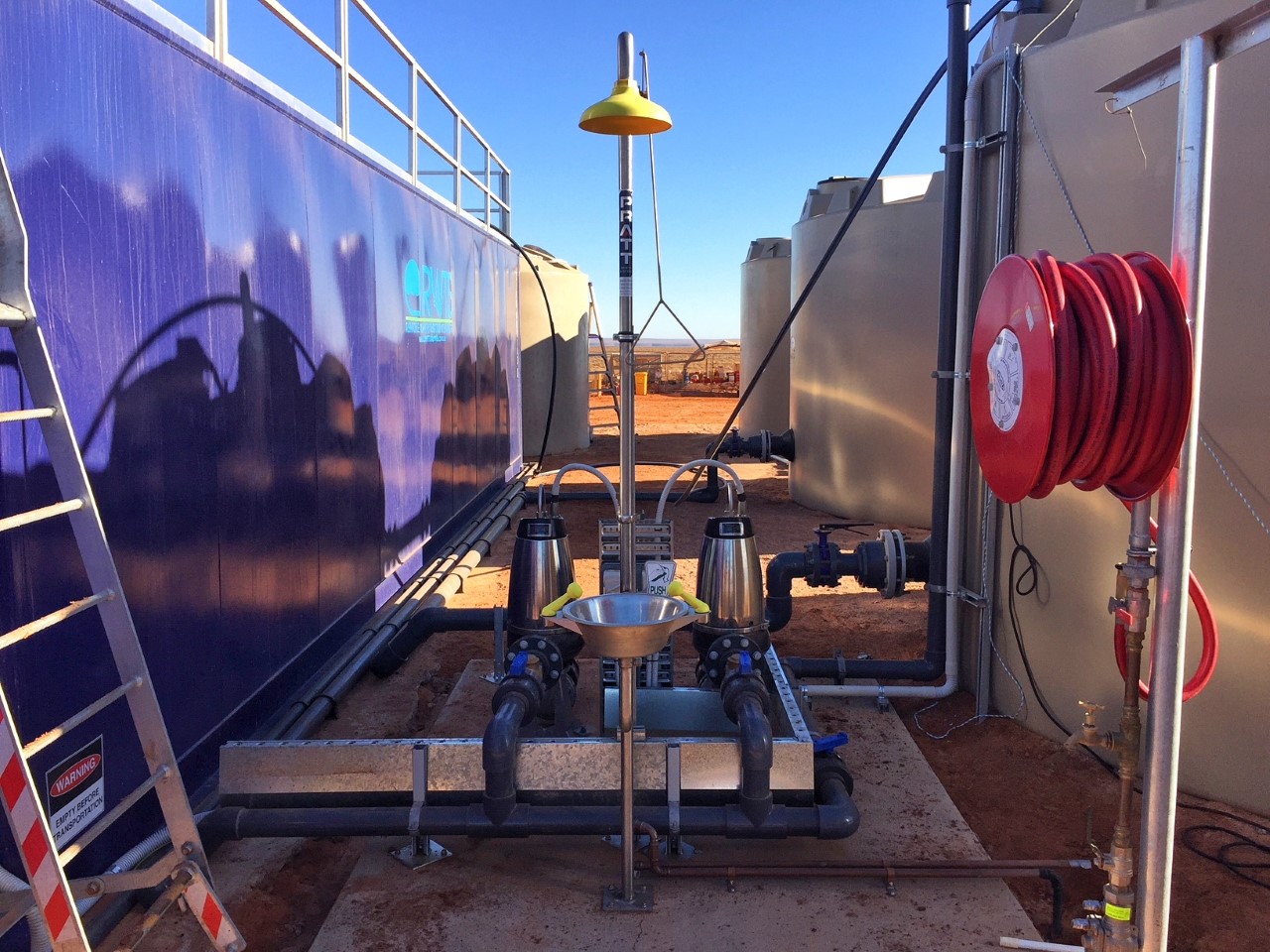

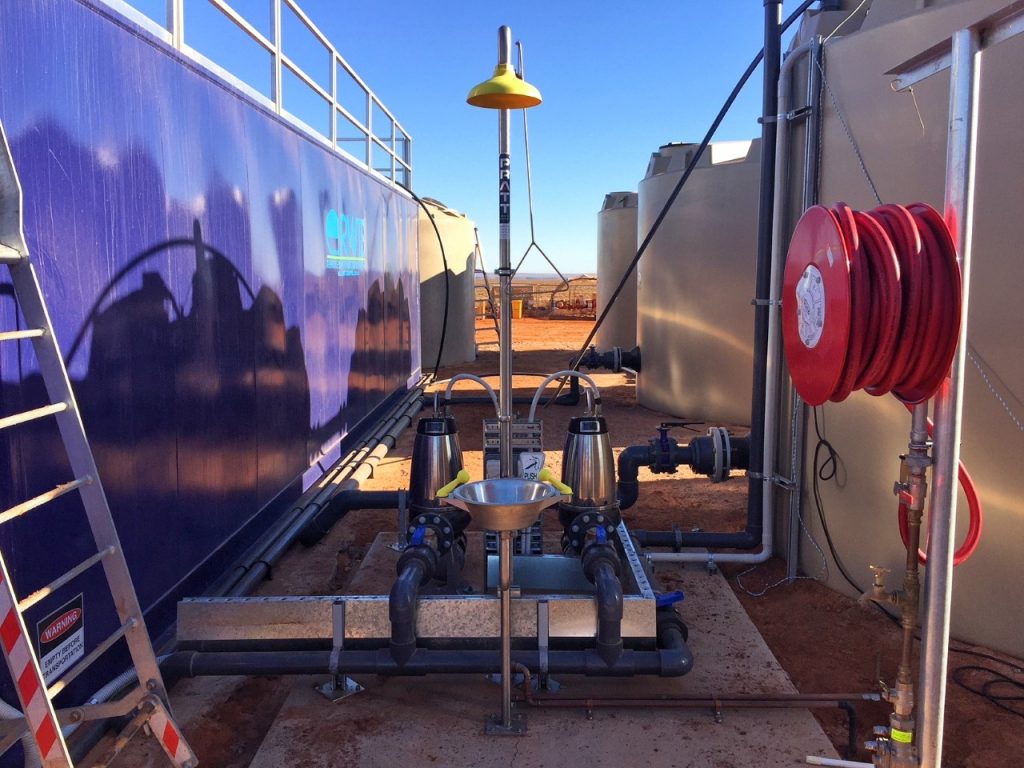

Another pair of Ecofarmer 250 units on deck for one of our mining clients in Western Australia. Arranged in twin train Ecofarmer 250 design with a Class A advanced media polishing packaged to ensure we meet our clients site compliance.

Client: Westgold

Location: Western Australia

Project: Westgold Cue Village WWTP upgrade

Solution: Twin Train Eco250 units with class a polishing package

Industry: Mining

BACKGROUND

The current waste water treatment facility situated at Cue Village Westgold needed to be replaced due to age and premature wear on the steel structure.

RWWA was asked to submit a proposal to design and construct a suitable waste water treatment system that suited the site hydraulic and incoming biological nutrient demand that would meet the release criteria as specified by governing body.

The new sewage treatment plant (STP) is designed to provide ongoing reliable service and to minimise maintenance requirements, ensuring ease of operation whilst maintaining reliable effluent quality and daily production.

THE RWWA SOLUTION

CUSTOM BUILT WASTEWATER TREATMENT PLANT

The site compliance targets are based on standard nutrient with Class A disinfection requiring less that 10 Ecoli per 100 ml of sample. Our Ecofamer SBR solution is packaged and delivered complete with our integral Class A glass media filtration system, that will further filter the supernatant from the sequencing batch reactors (SBR) to a higher class of final effluent, to release to ground.

Our glass media design is based on the ‘Drydan Glass,’ a validated and certified media product sold here in Australia. This is a highly refined crushed glass with excellent flux potential, allowing for full rejuvenation through a backwash and chemical clean process that extends to the filtration cycle, as oppose to conventional sand base media.

Our Class A media package is housed in a 20 ft high cube container beside our Ecofarmer treatment units. A dedicated feed pump on the VSD control, will continually recirculate the supernatant fluid over the glass media. Then the flow pace chlorine injection will sanitise the water keeping the media beds at optimal working order, whilst reducing fouling potential free residual oxidant. This will then be monitored and corrected for bacteriological control in the final effluent water body. Once the water has met specification within the chlorine contact residence time, a modulating valve will allow fluid to pass to the irrigation field.

As part of our advanced technology, a centralised Allen Bradley HMI and PLC will engage the operator allowing for full remote access, reducing any unnecessary call out fees.

Results:

The RWWA difference is our unique fabrication process of our engineered certified steel reactors that provide a generous 20 year chassis life guarantee. Our chassis are built from the ground up with 6 mm flat sheet formed and pressed for the walls giving the ultimate in rigidity and corrosion allowance. In addition, a suitable international or Jotun coating is applied to the internal and exterior of the box.

We are committed to providing the highest quality product and service to our customers.

NEED AN INNOVATIVE SYSTEM THAT DOES NOT FAIL?

If you are wanting a wastewater treatment system that works all day every day with the ability of remote monitoring, please call one of our friendly engineering team today to discuss your waste water issues and how we can help.