Atlas Iron awarded Maca a contract to carry out open pit mining services at the Corunna Downs iron project in the Pilbara region of Western Australia.

Client: Maca

Location: Pilbara region of Western Australia

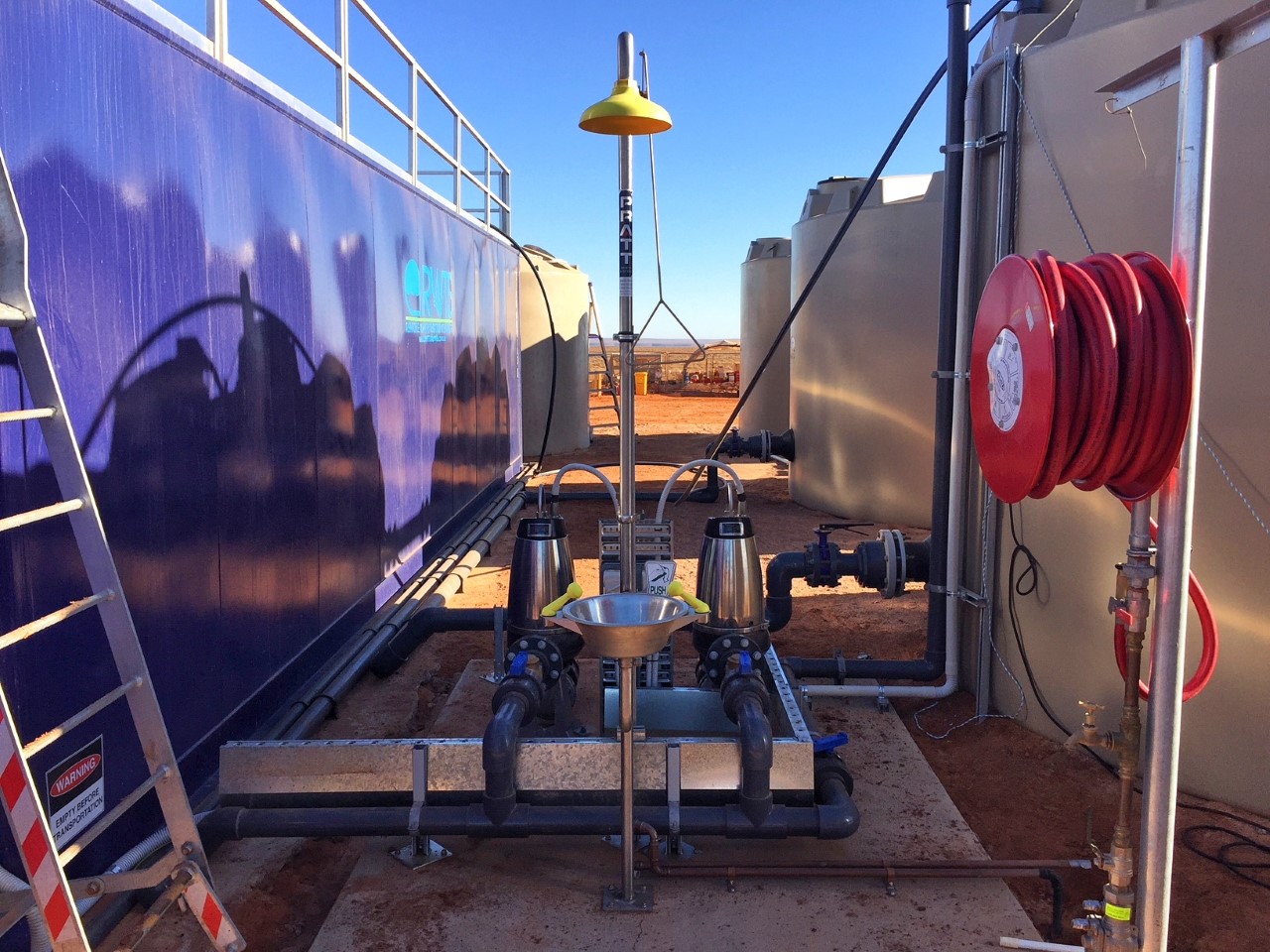

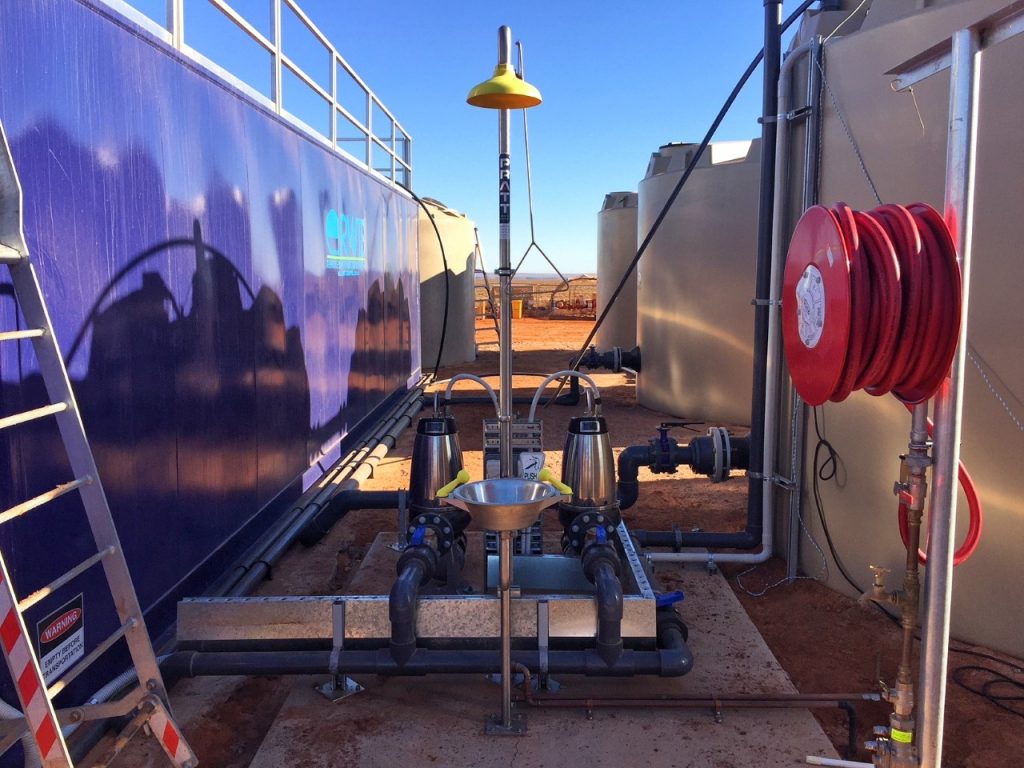

Technology implemented: Ecofarmer 50 series wastewater treatment plant

Industry: Mining

BACKGROUND

Corunna Downs, which is 100 per cent owned by Atlas Iron, is 33 kilometres south of Marble Bar and close to the iron ore miner’s Mt Webber project. The mine is expected to annually produce four million tonnes of iron ore initially. The life of the mine is expected to be between five and six years, with potential for future expansion as the current ore reserve considers only the above-water table resource.

Remote Water Treatment Services have designed in their custom Ecofarmer fabricated engineered reactor a waste water treatment system to cater for mining administration areas, ideal for low flow scenarios.

THE RWTS SOLUTION

Ecofarmer 50

The design known as the Ecofarmer 50 SBR caters for flows as low as 2,000 l – 10,000 l per day, an extremely versatile waste water treatment plant for the demand and environment.

The waste water treatment system takes it’s design and methodology from big brother the Ecofarmer 250, with the main process pump and motors located in the plant room, no moving parts are internal of the reactor allowing for ease of servicing.

The Ecofarmer design offers a treatment process with carbon and alkalinity supplementation dosed through our grundfos dosing platform controlled through the human–machine interface (HMI) ensuring optimal nutrient balancing through low demand periods. The system program looks for the level within the balance chamber automatically adjusting the cyclic nature of the process to achieve the desired aeration/mixing cycles. Further to this we have offered in our base offering a uninterruptible power supply (UPS) and Ewon remote modem for remote access into the programmable logic controller (PLC) and Human–Machine Interface (HMI), we can update software remotely and assist site based operators with handling issues that may arise without a call out fee.

Result

A waste water treatment system that caters for mining administration areas and met all council regulations and had a positive impact on the surrounding environment.

RWTS structurally engineered containerised plug and play Ecofarmer system was installed with in 5 days of mobilisation. The system is backed by RWTS remote dial in logging platform to allow our staff to maintain and record plant parameters from our Brisbane based office assisting our clients site operations.

NEED AN INNOVATIVE SYSTEM THAT DOES NOT FAIL?

If you are wanting a system that works all day every day with the ability of remote monitoring, please call one of our friendly engineering team today to discuss your treatment options.