Automative predictive maintenance technology allows us to program your plant machines and equipment with sensors that allow you to effectively monitor any issues. Our programmed sensors track critical operational information; like internal pressure, water flow rate and temperature; to alert your operation managers of any damages, wear or impending equipment failure.

Increase Efficiency

Automated wastewater treatment systems are poised to make treatment plants more efficient than ever before. The combination of the remotely accessible equipment and minute-to-minute data visualizations allows for boosted treatment capacity — like remote troubleshooting and maintenance, which will save your plant hours in downtime.

Another attractive advantage of programming and automating controls that gather data in wastewater treatment facilities is that your company has the chance to reduce the usage of chemical additives. From monitoring the depth of the sludge bed to fine-tuning the pH of water holding tanks, greater data availability can help reduce expenses and even prolong the life of critical equipment — like basins, filters and chemical pumps — by slowing down or eliminating corrosion.

Predictive diagnostics and maintenance

Automative predictive maintenance technology allows us to program your plant machines and equipment with sensors that allow you to effectively monitor any issues. Our programmed sensors track critical operational information; like internal pressure, water flow rate and temperature; to alert your operation managers of any damages, wear or impending equipment failure.

Increase Efficiency

Automated wastewater treatment systems are poised to make treatment plants more efficient than ever before. The combination of the remotely accessible equipment and minute-to-minute data visualizations allows for boosted treatment capacity — like remote troubleshooting and maintenance, which will save your plant hours in downtime.

With access to comprehensive and minute-to-minute plan data, it’s possible to now optimize wastewater plant processes in completely new way. Automation reduces the amount of labour that is generally demanded from water treatment employees as well as boosting plant efficiency, automated wastewater treatment systems can increase the amount of water that can be treated.

Reduced Need for Chemical Additives

Another attractive advantage of programming and automating controls that gather data in wastewater treatment facilities is that your company has the chance to reduce the usage of chemical additives. From monitoring the depth of the sludge bed to fine-tuning the pH of water holding tanks, greater data availability can help reduce expenses and even prolong the life of critical equipment — like basins, filters and chemical pumps — by slowing down or eliminating corrosion.

Predictive diagnostics and maintenance

Automative predictive maintenance technology allows us to program your plant machines and equipment with sensors that allow you to effectively monitor any issues. Our programmed sensors track critical operational information; like internal pressure, water flow rate and temperature; to alert your operation managers of any damages, wear or impending equipment failure.

Increase Efficiency

Automated wastewater treatment systems are poised to make treatment plants more efficient than ever before. The combination of the remotely accessible equipment and minute-to-minute data visualizations allows for boosted treatment capacity — like remote troubleshooting and maintenance, which will save your plant hours in downtime.

Similarly, our automated systems can also reduce the amount of water that is lost during the treatment process, saving your companies plants and your operation additional resources.

Constant Access to Data and Ongoing Sampling

In wastewater treatment and other industry processes, “grab sampling” has long been the process operations rely on to achieve data visibility. The problem with this method is that it requires ongoing labour and it only provides a snapshot of conditions when the sample was taken. Programming and automating the sampling process is a more precise way to identify patterns and trends, engage in more meaningful analysis, and make timelier decisions before small problems become bigger ones.

Furthermore automating data isn’t just about collecting more data, it is also about obtaining more qualified data. Our clients can engage remotely online to monitor in real-time, saving the hassle of sending samples to a lab for analysis. Not only will you save time with our automation but also you are guaranteed that the samples will not change in composition between the time the sample is gathered and when it arrives to the lab for processing.

Increasing treatment capacity

With access to comprehensive and minute-to-minute plan data, it’s possible to now optimize wastewater plant processes in completely new way. Automation reduces the amount of labour that is generally demanded from water treatment employees as well as boosting plant efficiency, automated wastewater treatment systems can increase the amount of water that can be treated.

Reduced Need for Chemical Additives

Another attractive advantage of programming and automating controls that gather data in wastewater treatment facilities is that your company has the chance to reduce the usage of chemical additives. From monitoring the depth of the sludge bed to fine-tuning the pH of water holding tanks, greater data availability can help reduce expenses and even prolong the life of critical equipment — like basins, filters and chemical pumps — by slowing down or eliminating corrosion.

Predictive diagnostics and maintenance

Automative predictive maintenance technology allows us to program your plant machines and equipment with sensors that allow you to effectively monitor any issues. Our programmed sensors track critical operational information; like internal pressure, water flow rate and temperature; to alert your operation managers of any damages, wear or impending equipment failure.

Increase Efficiency

Automated wastewater treatment systems are poised to make treatment plants more efficient than ever before. The combination of the remotely accessible equipment and minute-to-minute data visualizations allows for boosted treatment capacity — like remote troubleshooting and maintenance, which will save your plant hours in downtime.

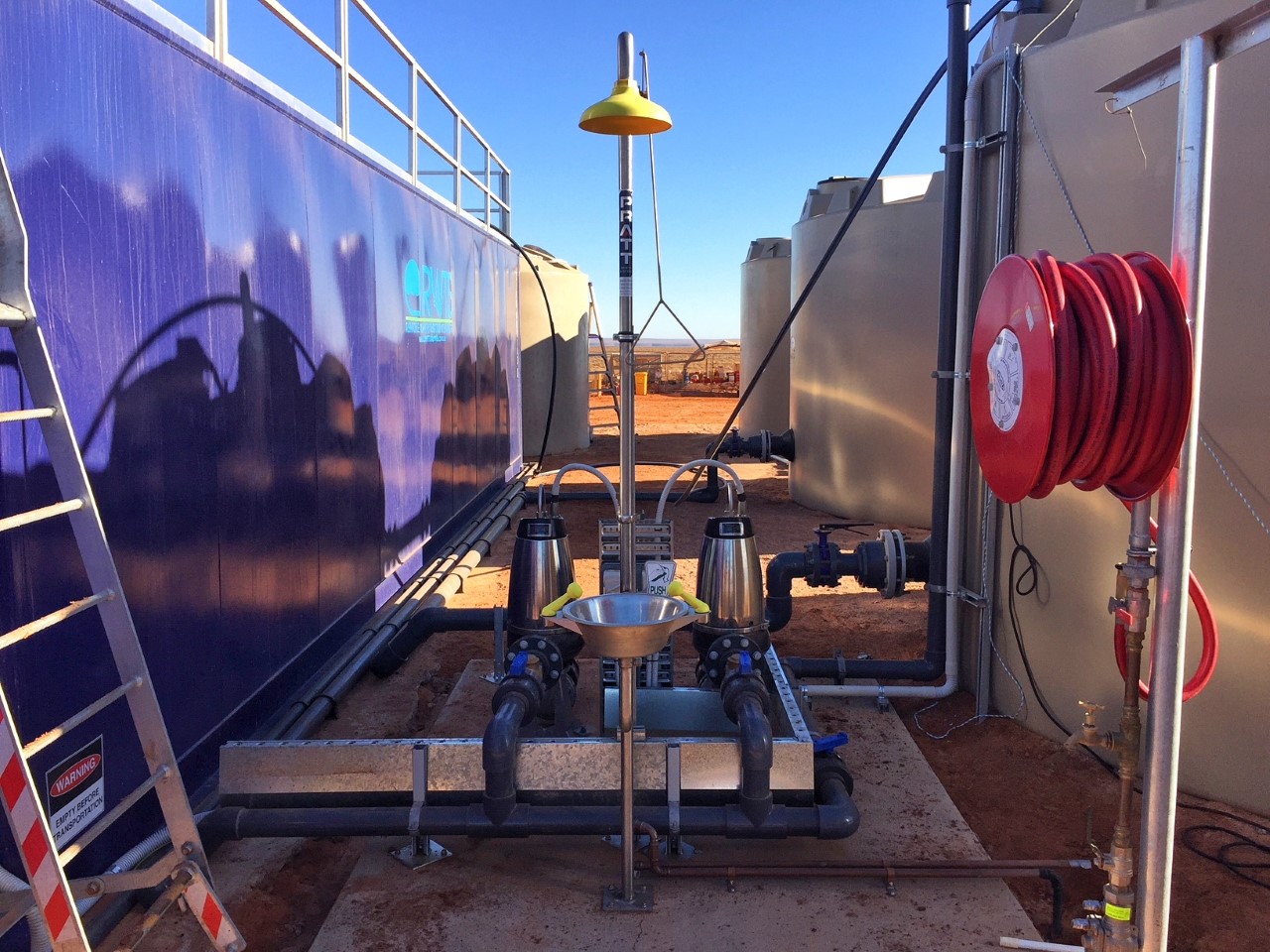

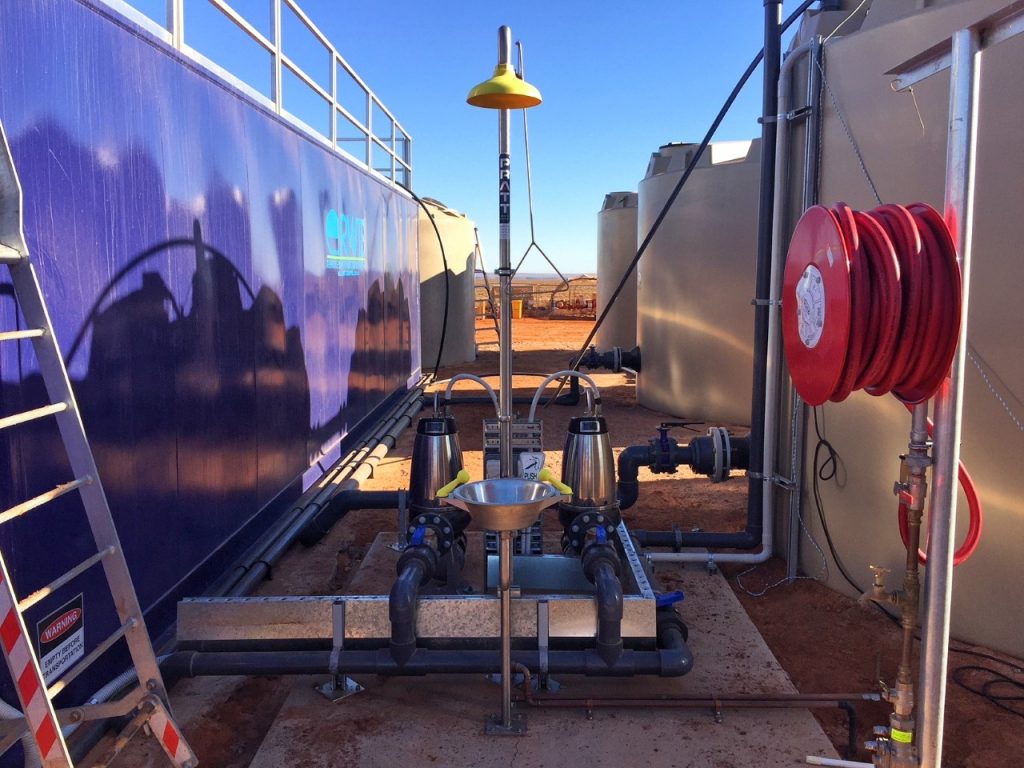

What are the advantages of automation for wastewater treatment plants?

Programming and automation in recent times has become a necessity in wastewater treatment plant solutions. This service is one of the most critical industrial-level activities today when wastewater and water management is concerned. Here are some of the ways this technology is making the process more efficient and cost-effective.

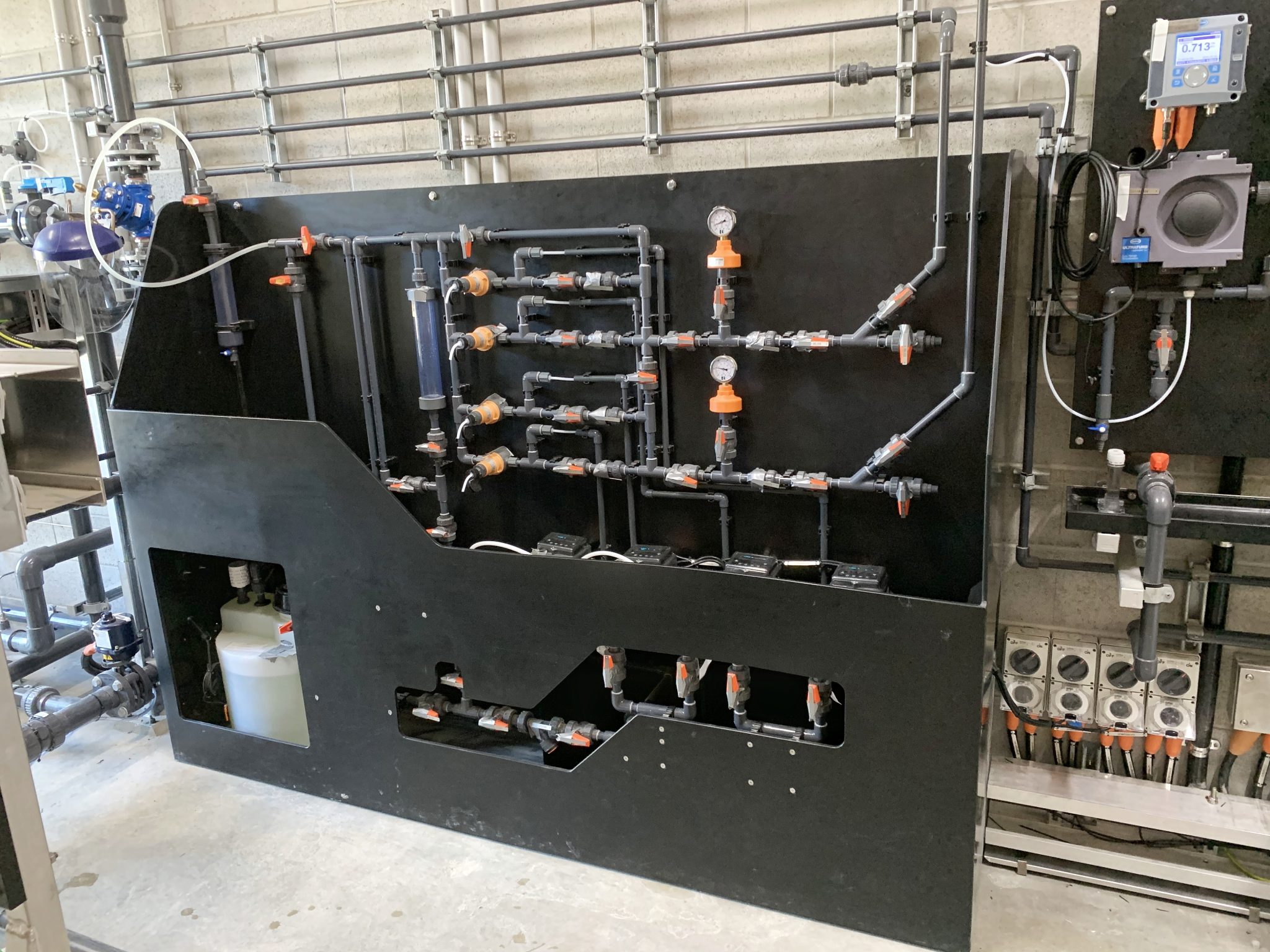

Lower Energy Costs

Not surprisingly, energy use is the single biggest expense for wastewater treatment plants. Programming and automating infrastructure provides one way to reduce energy expenditures associated with a number of critical water treatment processes.

For example the blowers located in holding basins, which keep the water purified. Blowers can account for up to 50% of a water treatment plant’s total energy consumption. Programming and automation can improve cost effectiveness with reducing energy consumption through data collection. Instead of operating the blowers constantly, at a fixed speed, plants can use information about effluent levels in holding basins to apply air and remove solids only when it’s necessary to do so. This reduces energy costs, helps maintain a steady flow and reduces wear and tear on equipment.

Similarly, our automated systems can also reduce the amount of water that is lost during the treatment process, saving your companies plants and your operation additional resources.

Constant Access to Data and Ongoing Sampling

In wastewater treatment and other industry processes, “grab sampling” has long been the process operations rely on to achieve data visibility. The problem with this method is that it requires ongoing labour and it only provides a snapshot of conditions when the sample was taken. Programming and automating the sampling process is a more precise way to identify patterns and trends, engage in more meaningful analysis, and make timelier decisions before small problems become bigger ones.

Furthermore automating data isn’t just about collecting more data, it is also about obtaining more qualified data. Our clients can engage remotely online to monitor in real-time, saving the hassle of sending samples to a lab for analysis. Not only will you save time with our automation but also you are guaranteed that the samples will not change in composition between the time the sample is gathered and when it arrives to the lab for processing.

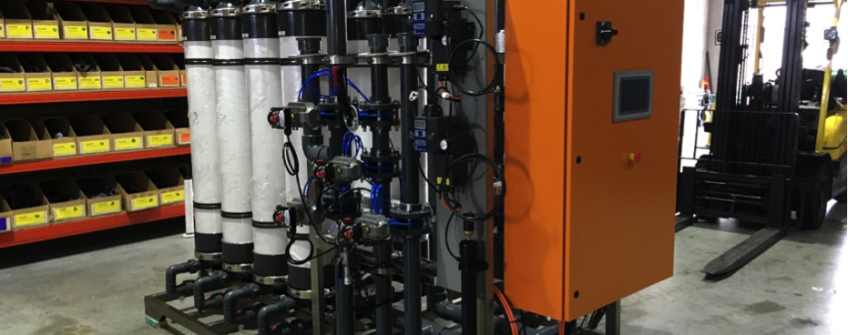

Increasing treatment capacity

With access to comprehensive and minute-to-minute plan data, it’s possible to now optimize wastewater plant processes in completely new way. Automation reduces the amount of labour that is generally demanded from water treatment employees as well as boosting plant efficiency, automated wastewater treatment systems can increase the amount of water that can be treated.

Reduced Need for Chemical Additives

Another attractive advantage of programming and automating controls that gather data in wastewater treatment facilities is that your company has the chance to reduce the usage of chemical additives. From monitoring the depth of the sludge bed to fine-tuning the pH of water holding tanks, greater data availability can help reduce expenses and even prolong the life of critical equipment — like basins, filters and chemical pumps — by slowing down or eliminating corrosion.

Predictive diagnostics and maintenance

Automative predictive maintenance technology allows us to program your plant machines and equipment with sensors that allow you to effectively monitor any issues. Our programmed sensors track critical operational information; like internal pressure, water flow rate and temperature; to alert your operation managers of any damages, wear or impending equipment failure.

Increase Efficiency

Automated wastewater treatment systems are poised to make treatment plants more efficient than ever before. The combination of the remotely accessible equipment and minute-to-minute data visualizations allows for boosted treatment capacity — like remote troubleshooting and maintenance, which will save your plant hours in downtime.